Balancing the power grid by generating heat and cold

At the ‘European Energy Forum’ (EUREF), beneath the gasometer in Berlin-Schöneberg, GASAG Solution Plus is testing a Power-to-Heat/Power-to-Cold installation that is unique in Germany as part of WindNODE. Their first learning: demand is greater than anticipated.

“The intelligence lies in controlling the system”

“You wouldn't believe how often wind turbines around Berlin had to be shut down in 2017,” says Frank Mattat while opening one of the high glass doors to the energy hub of the European Energy Forum in Berlin. Towering above him is the old gasometer of Schöneberg, a symbol of the energy supply in the 19th century. “If the wind turbines had been left on, Berlin could have been supplied with power for ten days,” continues the CEO of GASAG Solution Plus.

The GASAG Solution Plus installation in the hall behind the glass door should help put excess electricity in the grid to good use. It is the first and currently only installation of its kind in Germany. It transforms surplus electricity into hot and cold water, a perfect representation of the energy supply of the 21st century: the shutdown of wind turbines should soon be a thing of the past.

▶ Play

The YouTube video will only load and play after clicking. By clicking the video, you agree to Google’s data protection policy.

53 per cent renewable energy in the north-east of Germany

From the upper ring of the old gasometer, you can see the entire city: blue solar panels glint on the rooftops of the housing blocks and company buildings; where the metropolis fades into the Brandenburg countryside, dozens of windmills dot the landscape. Nowhere is the share of renewables in the power mix as high as in the north-east of Germany: over 53 per cent and rising. For this reason, over 70 partners are involved in the WindNODE project, mainly so that energy consumers can align their electricity demand with the fluctuating offer of wind turbines and solar plants, and in doing so make the operation of the power grids in the north-eastern grid area fit for the energy transition. WindNODE is part of the ‘Smart Energy Showcase’ (SINTEG) support programme and is sponsored by the Federal Ministry for Economic Affairs and Energy (BMWi) until 2020.

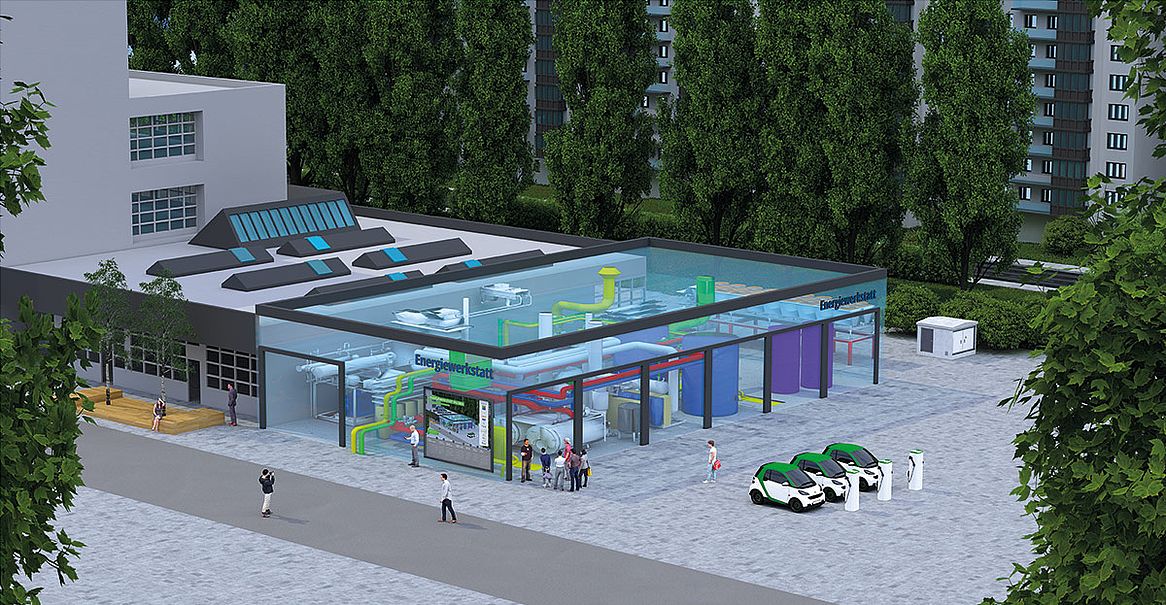

The EUREF campus is an important piece of the WindNODE puzzle, right at the heart of Berlin: at the foot of the gasometer, the S-train runs past the former industrial site; the campus was opened only ten years ago. Institutes of Berlin’s universities have settled here, as well as energy start-ups and renowned companies, creating a think tank for the energy transition. By now, some 3,500 people work here, and new offices and research facilities continue to rise up from the ground.

Sector coupling: how it works

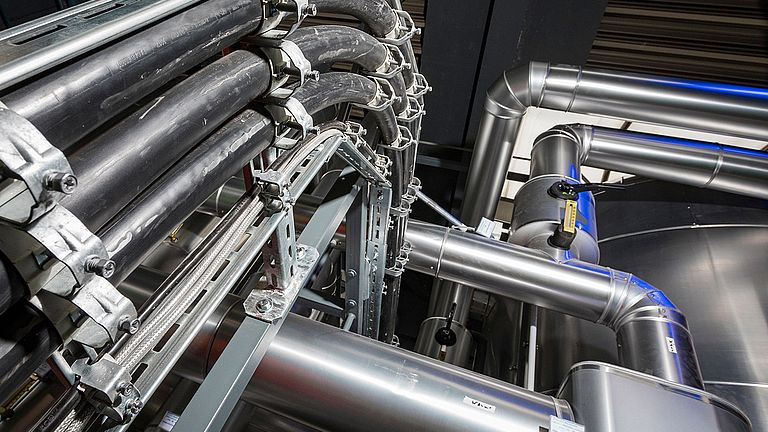

The size of a machine hall, the GASAG Solution Plus energy hub is located at the centre of the campus. From here, a 2.5 kilometre long pipeline system supplies heating and cooling to the office buildings and provides cooling for the computer and server rooms.

▶ Play

The YouTube video will only load and play after clicking. By clicking the video, you agree to Google’s data protection policy.

At the same time, the energy hub is an experimental set-up for the energy transition: “Here, we want to show how sector coupling works,” Mattat says about the project at EUREF, which is also part of WindNODE, ‘showcasing smart energy systems from north-eastern Germany’.

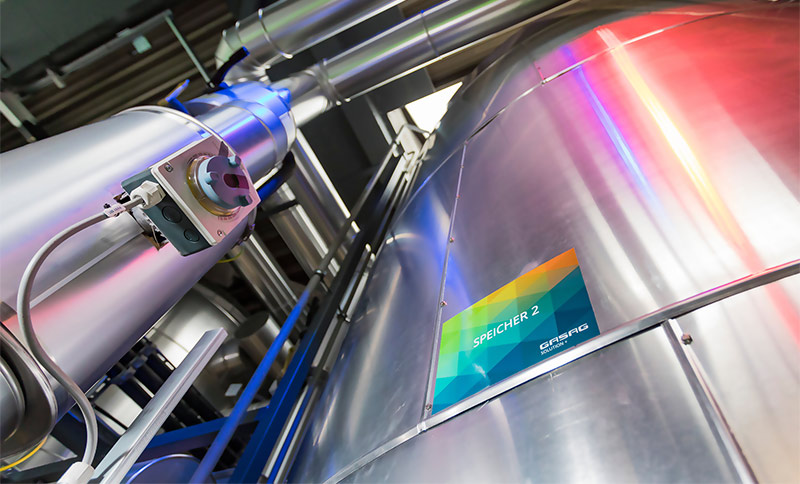

Mattat stops in front of two large silver cylinders, rising six metres high above the roof of the energy hub: “These water tanks contain 22 cubic metres, forming the heart of the Power-to-Heat/Power-to-Cold installation,” he explains loud enough to be heard over the constant roar of the ventilation system and the high-pitched whirr of the pumps starting up. The water in these storage tanks is heated by the large electrical flow heater located in front of the reservoirs and that resembles a gas- or oil-fired boiler, such as can be found in millions of households. The heater inside is invisible behind the red and grey metal panelling and has an output of 500 kilowatts; it can therefore consume as much electricity as produced by a small wind turbine or a medium-sized solar plant.

Compressors that look like miniature submarines

The cooling unit is even more impressive: to Mattat’s right, two compressors have been constructed with pressurizers of almost two metres long, resembling miniature submarines. The dimensions are formidable, but the principle is the same as that of any household refrigerator: cold is generated through compression and release. Here, it is merely bigger. Much bigger.

What happens here is what experts call “Power-to-Heat” (PtH) and “Power-to-Cold” (PtC): the use of electricity to heat up or cool down water. Until now, the heating of the EUREF campus of GASAG Solution Plus is mainly supplied by a biomethane combined heat and power (CHP) unit (400 kWel, 460 kWth), an own CHP unit (50 kWel, 100 kWth) running on natural gas as well as two natural-gas peak-load boilers with a capacity of 2,100 kilowatt each. The cooling units run on green electricity. All in all, this is already leading to a CO2-neutral supply of the campus. The aim is to mainly operate the large water reservoirs when there is a particularly high supply of electricity from solar plants or wind power in north-eastern Germany. “This is how we help avoid that renewable energy generating units have to be shut down,” explains Mattat.

Heating and cooling when there is a lot of electricity

However, what sounds simple in principle is challenging in practice. When should the electric heating and cooling units be activated? When excess power is available on the market and the prices on the Leipzig power exchange are low, that much is clear. But in order to make the operation profitable as well, the installations should also take off electricity when it is actually cheapest; in other words, when the electricity price on the exchange drops to 10 euros per megawatt-hour or, even better, when electricity no longer costs anything at all. After all, that is when the contribution of electrical heating and cooling units to balance electricity generation and consumption is at its highest. To this end, however, the heat storage units have to be empty at the right moment, for instance during the winter: their hot water therefore needs to be used anticipatorily so that it has cooled down to the minimum temperature in the heating system. The large reservoirs take four hours to heat the water; these hours should coincide with a maximum power supply and minimum electricity prices as much as possible.

“In preparation of the WindNODE experiment, we simulated the entire energy system on the EUREF campus with all its consumers, boilers, reservoirs as well as the heating and cooling units,” explains Mattat. It was then tested how this complex system could be managed in the best possible way using the weather data and electricity prices of previous years, leading to further improvements. Mattat: “Innovation does not consist of individual components, but in how the system is managed. That is why we developed our own self-learning computer system that is equipped with artificial intelligence - the EcoTool.”

Cold is more profitable than heat

The result of the simulations surprised GASAG Solution Plus: “For the most profitable operation, we have to use the cooling units much more intensively than the electric heaters,” says Mattat, as the cheap electricity available on the energy exchange for the compressors then replaces the comparably expensive electricity that is otherwise used to operate the cooling units. However, when the electric heater is activated, it competes with the water heating by the biomethane cogeneration unit. Even before the official opening of the installations in September 2017, GASAG Solution Plus also learned many other things.

Inside the energy hub, Frank Mattat walks along green paths; literally: after the official opening, a veritable rush of visitors is expected and GASAG Solution Plus had the paths for the visitors marked in bright green. Eight stops lie between the heating and cooling units and the point of the installation where the heating and cooling lines from the energy hub connect to the campus pipeline system. Tablet in hand, Mattat shows the videos that GASAG Solution Plus will use to explain the details of the installation to future visitors: depending on their prior knowledge, there are three different levels of detail for their visit to the energy hub at EUREF.

WindNODE as an example to supply neighbourhoods

GASAG Solution Plus considers the project at EUREF as a ‘test run’: “We’ve arrived at the point where we are also integrating Power-to-Heat in other projects within the city as well,” says Mattat. In a neighbourhood with about 1,000 living units in Mariendorf, Mattat’s employees are combining a CHP unit with a Power-to-Heat installation that is operated with the self-produced electricity from the thermal power station. In Mariendorf, solar panels are also being installed on the façades to generate power, as well as batteries to store electricity. For the tenants, this means permanently cheap heating but also an electricity supply that is not subject to price fluctuations.

The decisive factor is that the interplay between small power stations, solar installations and the production of heat and cold is controlled. The objective of GASAG Solution Plus: “With this in mind, we want to equip neighbourhoods throughout Germany with a climate-friendly energy supply that also makes it possible to switch from coal-fired power plants to wind turbines and solar plants,” says a thoroughly convinced Mattat. At EUREF in Berlin-Schöneberg, the future has already begun.

Eight questions for...

We have simulated the entire set-up on the site: to this end, we modelled heating and cooling units with all consumers, the entire heating and cooling demand in the quarter and all technical and economic possibilities and restrictions, and tested this model using electricity market data from previous years. This way, we wanted to find out what was the most sensible operation mode for the energy hub.

Theoretically, much is possible. Practically, however, such installations cannot be switched on and off depending on the electricity price. There are also technical specifications such as the interworking of the electrical Power-to-Heat installation with the biomethane CHP unit: here, we have to take into account how long it takes to start up and shut down these installations and we have to take care that we do not reduce the service life of the systems or unduly increase the need for maintenance as a result of the operation mode. The individual installations have to interact like clockwork and also adjust hourly to new weather or electricity price forecasts. This can only be done fully automatically, with artificial intelligence and permanently learning control algorithms, as no one is still able to make the calculations by hand.

Before the start of the project, we assumed that we could use the water tanks mainly as heat storage units during the winter, and that in case of high temperatures during the summer, mainly the cooling units would be active. In between, we expected months during which one of the 22 cubic metre boilers would be used for cooling and the other one for heating. However, this was not the case.

The simulations showed that it made more sense to mainly use both reservoirs for cold storage throughout the year, also from an economical point of view. This is because the generation of cold water is much more profitable than the generation of hot water. And if we use the entire volume of the reservoirs for cooling, we can time the operation of the cooling units even better with the times when electricity is actually cheapest.

We’ve learned that the water tanks should be bigger from an economic point of view. Much bigger. Preferably ten or even twenty times as big. In principle, however, the Federal Government must also create the framework for sector coupling for this purpose (as Frank Mattat explains in his Interview). Here on campus, we simply do not have enough room.

We would have much greater liberty to plan the operation of our installations exactly at those times when the electricity surplus is at its highest and the prices at their lowest. Right now, it takes two hours until the compressors have cooled the water tanks down to the minimum value of about 8 degrees Celsius. And as much as four hours until the Power-to-Heat installations or the CHP unit have heated the water up to about 90 degrees Celsius. Because the water tanks are limited to 22 cubic metres, they can only store hot or cold water for a few hours.

We could for example cool down the water in the storage tanks during the night, when the electricity only costs 10 euro per megawatt-hour. We could then use this cold water to cool the server rooms the whole next day. We would be able to relieve the power grid even more, as our machines would be able to contribute to the balancing of supply and demand to a much greater extent.

We are currently trying to not just use the water boiler itself for storage, but also part of the pipeline system that was constructed here on the EUREF campus. If we can integrate the volume of the local heating network, we can already double the storage capacity. This also makes it easier for us to choose when we purchase electricity.

Project figures

- Power-to-Heat installation: 500 kW heat output

- Power-to-Cold installation (two compression refrigeration machines): 1,000 kW of cold capacity per machine, 278 kW of energy consumption per machine

- Storage volume per water tank: 22 m³

- CHP unit: 400 kWel, 460 kWth

- Length of the local heating pipelines on site: 2.5 km

- Funding received under the SINTEG programme: €270,000

Past, present and future

The planning for the WindNODE project started in 2016; in the autumn of 2017, the Power-to-Heat/Power-to-Cold installation was commissioned. In the autumn of 2018, the site will be officially opened for visitors.

Visits

As of autumn 2018, group tours are offered. If you are interested, you can book directly at www.energiewende-erleben.de. You can find more information here.

Contribution

GASAG Solution Plus contributes to grid stability by constructing and operating a Power-to-Heat/Power-to-Cold plant at the EUREF campus in Berlin. At the same time, the Power-to-Heat/Power-to-Cold system will be integrated into the campus's existing local heating and cooling system, which on the heating side is primarily supplied by a biomethane-fired combined heat and power unit (CHP).

GASAG Solution Plus selected the EUREF campus for the WindNODE project because this is where expertise and passion about the energy transition meet. On average, the power system supplies about 150,000 square metres of office space and as such already fulfils the climate protection targets of the city of Berlin for 2050: the heat supply on the EUREF campus is climate-neutral.